In the world of industrial machinery and electrical equipment, precision and reliability are paramount. Two critical components that play a significant role in the performance of various mechanical and electrical systems are carbon brush holders and custom springs. Understanding their functions, applications, and the manufacturing processes behind them is essential for ensuring optimal performance and longevity of the equipment. This article delves into the intricacies of carbon brush holders and custom spring manufacturing, highlighting their importance and the expertise required to produce these components.

Carbon Brush Holders: Ensuring Efficient Electrical Contact

What are Carbon Brush Holders?

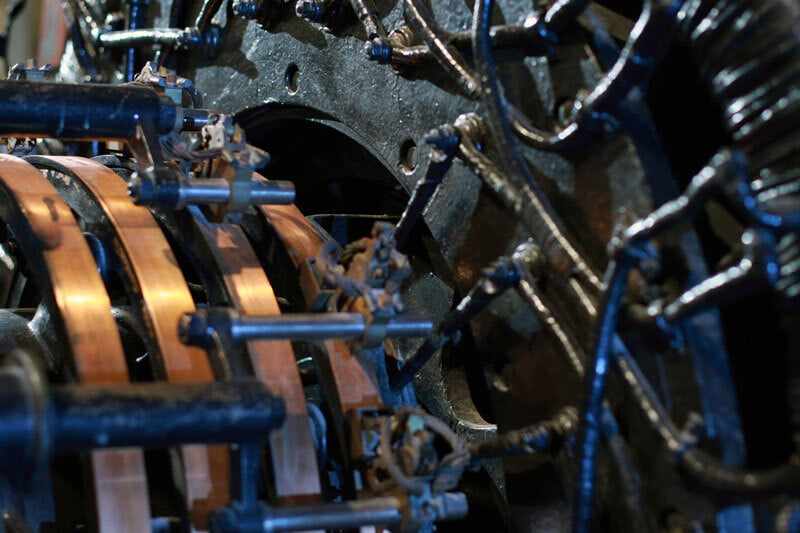

Carbon brush holders are devices used to house and support carbon brushes in electrical machines, such as motors and generators. The primary function of carbon brush holders is to maintain a stable and reliable electrical contact between the rotating parts (commutators or slip rings) and the stationary parts of the machine. This contact is crucial for the efficient transfer of electrical current.

Importance and Applications

Electrical Motors and Generators: Carbon brush holders are essential in ensuring the smooth operation of electric motors and generators. They help in reducing electrical noise and wear and tear, thus extending the lifespan of the equipment.

Wind Turbines: In wind turbines, carbon brush holders play a vital role in the transfer of electrical power from the rotating blades to the stationary part of the turbine, ensuring efficient energy generation.

Automotive Industry: Carbon brush holders are used in alternators and starter motors, providing reliable electrical contact for efficient vehicle operation.

Manufacturing Process

The manufacturing of carbon brush holders involves precision engineering and high-quality materials. Key steps include:

Material Selection: Choosing the right materials, typically copper or brass, for their excellent conductivity and durability.

Design and Prototyping: Creating detailed designs and prototypes to ensure the brush holders meet specific requirements.

Machining and Fabrication: Using advanced machining techniques to fabricate the brush holders with precise dimensions and tolerances.

Quality Control: Rigorous testing and quality control to ensure the brush holders perform reliably under various conditions.

Custom Spring Manufacturing: Tailoring Solutions for Diverse Applications

What are Custom Springs?

Custom springs are tailored solutions designed to meet specific requirements in various mechanical systems. They are used to store and release energy, absorb shock, maintain force between contacting surfaces, and manage tension in different applications. Custom springs come in various types, including compression springs, extension springs, torsion springs, and constant torque springs.

Importance and Applications

Automotive Industry: Custom springs are used in suspension systems, seat mechanisms, and engine components to provide stability and performance.

Aerospace: Precision springs are critical in aerospace applications, where they must withstand extreme conditions and perform reliably.

Medical Devices: Custom springs are used in medical equipment, such as surgical instruments and diagnostic devices, requiring high precision and reliability.

Consumer Electronics: Springs in electronic devices, such as mobile phones and laptops, provide functionality and durability.

Manufacturing Process

The manufacturing of custom springs involves several steps to ensure they meet specific design and performance criteria:

Design and Engineering: Collaborating with clients to understand their requirements and creating detailed designs using CAD software.

Material Selection: Choosing the appropriate materials, such as stainless steel, high-carbon steel, or specialized alloys, based on the application requirements.

Prototyping: Producing prototypes to test and refine the design before full-scale production.

Coiling and Forming: Using advanced machinery to coil and form the springs with precise dimensions and tolerances.

Heat Treatment: Applying heat treatment processes to enhance the strength and durability of the springs.

Surface Finishing: Adding surface finishes, such as plating or coating, to improve corrosion resistance and aesthetics.

Quality Assurance: Conducting rigorous testing and inspections to ensure the springs meet all specifications and performance standards.

Conclusion

Carbon brush holders and custom springs are indispensable components in a wide range of industrial and electrical applications. Their precise manufacturing and high-quality materials are crucial for the reliability and efficiency of various systems. By understanding the importance and manufacturing processes of these components, industries can ensure optimal performance and longevity of their equipment. Whether it's ensuring stable electrical contact with carbon brush holders or tailoring custom springs for specific applications, the expertise and attention to detail in their production are paramount.

.png)

.jpg)

.png)

Write a comment ...