In the realm of industrial machinery and electric motor applications, the quality of components like carbon brushes and torque springs plays a crucial role in ensuring optimal performance and longevity. Leading manufacturers of these components provide essential solutions that cater to various industries, enhancing the efficiency and reliability of equipment and devices.

Carbon Brushes: The Backbone of Electric Motors

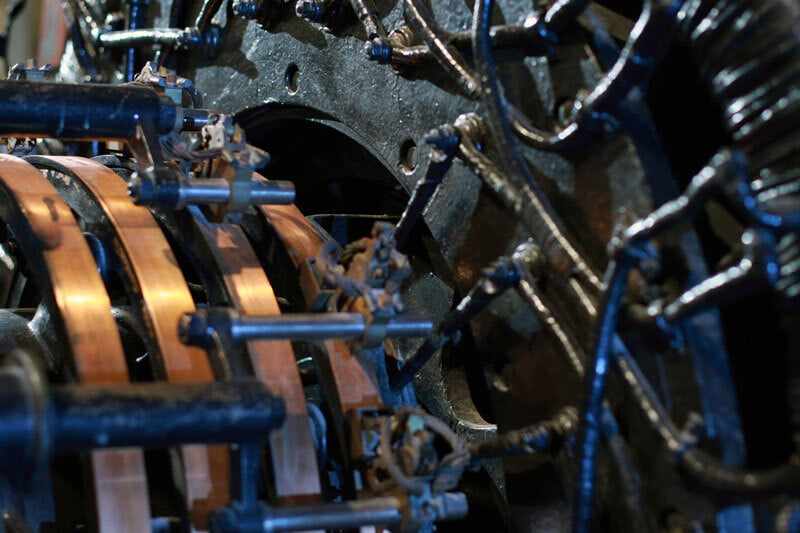

Carbon brushes are vital components in electric motors, generators, and other rotating machinery. They ensure the efficient transfer of electrical current between the stationary parts (stator) and the moving parts (rotor) of a machine, facilitating its smooth operation. The performance and lifespan of these machines heavily depend on the quality and durability of the carbon brushes used.

Key Features:

High Conductivity: Made from high-grade carbon or graphite, these brushes provide excellent electrical conductivity, ensuring efficient current transfer.

Durability: Designed to withstand wear and tear, high temperatures, and friction, carbon brushes offer long-lasting performance.

Self-Lubricating Properties: Some carbon brushes feature self-lubricating properties to reduce friction and wear on the commutator or slip rings.

Customizable: Available in various sizes, shapes, and grades to meet specific requirements of different motors and applications.

Benefits:

Enhanced Motor Efficiency: High-quality carbon brushes ensure optimal current transfer, leading to efficient motor performance.

Reduced Maintenance Costs: Durable and self-lubricating brushes require less frequent replacements, reducing maintenance costs.

Improved Reliability: Consistent performance and reduced wear on other motor components enhance the overall reliability and lifespan of the equipment.

Versatility: Suitable for a wide range of applications, including automotive, industrial machinery, power tools, and household appliances.

Torque Springs: Precision in Motion Control

Torque springs are mechanical devices used to store and release rotational energy in a controlled manner. They are essential in applications requiring precise motion control, such as in clocks, automotive components, and various industrial machines. Leading manufacturers design and produce torque springs manufacturer with high precision to meet the specific needs of different industries.

Key Features:

Material Quality: Made from high-strength materials such as stainless steel or high-carbon steel, ensuring durability and resistance to fatigue.

Precision Engineering: Manufactured with tight tolerances to provide accurate and consistent performance in various applications.

Custom Designs: Available in custom designs and specifications to meet the unique requirements of different industries and applications.

High Load Capacity: Capable of handling significant loads and stresses, ensuring reliable performance under demanding conditions.

Benefits:

Reliable Motion Control: Torque springs provide precise and reliable motion control, essential for applications requiring accurate rotational movements.

Extended Service Life: High-quality materials and precision engineering ensure long-lasting performance and resistance to wear and fatigue.

Versatility: Suitable for a wide range of applications, from automotive components and industrial machinery to medical devices and consumer products.

Customization: Manufacturers offer customized solutions to meet specific application requirements, ensuring optimal performance and compatibility.

Leading Manufacturers: Quality and Innovation

Leading manufacturers of carbon brushes and torque springs are known for their commitment to quality, innovation, and customer satisfaction. They leverage advanced manufacturing technologies and rigorous quality control processes to produce components that meet the highest industry standards.

Advantages of Choosing Leading Manufacturers:

Expertise and Experience: Established manufacturers have extensive experience and expertise in producing high-quality components for various industries.

Advanced Technology: Utilization of advanced manufacturing technologies and processes ensures precision and consistency in product quality.

Customization Options: Ability to provide customized solutions tailored to specific application requirements, ensuring optimal performance and compatibility.

Reliable Supply Chain: Strong supply chain capabilities ensure timely delivery and consistent availability of products.

Conclusion

Carbon brushes and torque springs are essential components that play a critical role in the performance and reliability of various machines and devices. By choosing high-quality products from leading manufacturers, industries can ensure efficient operation, reduced maintenance costs, and enhanced equipment longevity. Whether it's for electric motors, industrial machinery, or precision motion control applications, investing in quality components is key to achieving optimal performance and reliability.

.png)

.jpg)

.png)

Write a comment ...