Electric motors are fundamental to countless applications, from household appliances to industrial machinery. A key aspect of maintaining the efficiency and longevity of these motors lies in understanding and managing their core components, particularly electric motor brushes and carbon brushes. These brushes play a vital role in ensuring smooth operation and reliable performance.

Electric Motor Brushes: The Backbone of Motor Functionality

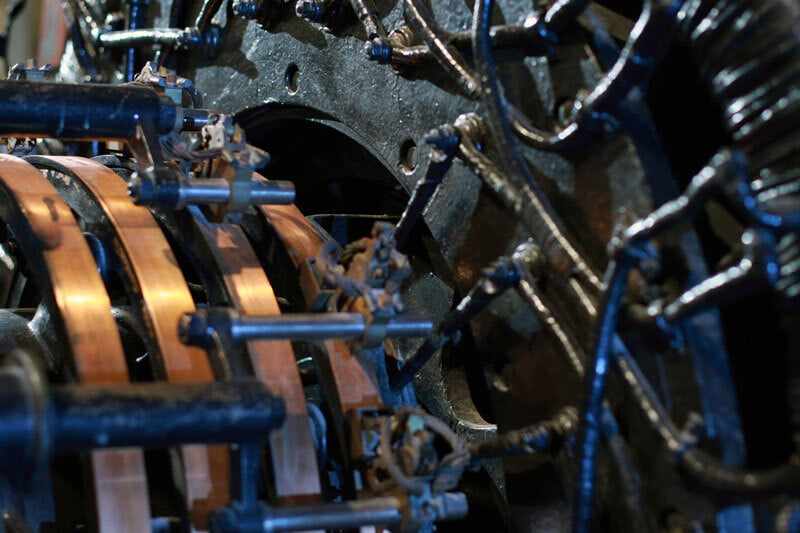

Electric motor brushes are critical elements in the functioning of electric motors. They facilitate the transfer of electrical current between the stationary parts (stator) and the rotating parts (rotor) of the motor. This transfer is essential for the motor's operation, allowing it to convert electrical energy into mechanical energy.

Key Features:

Conductive Materials: Typically made from materials like carbon, graphite, or a combination of carbon and other conductive substances to ensure efficient current transmission.

Shape and Size: Available in various shapes and sizes to fit different types of motors and specific application requirements.

Spring Mechanism: Often equipped with a spring to maintain consistent pressure on the commutator or slip ring, ensuring continuous electrical contact.

Wear Resistance: Designed to withstand friction and heat, thereby reducing wear and extending the operational life of the motor.

Benefits:

Efficient Power Transfer: Ensures that electrical current is effectively transferred, enabling smooth motor operation.

Reduced Electrical Noise: High-quality brushes minimize electrical noise and sparking, contributing to quieter motor performance.

Extended Motor Life: Properly functioning brushes protect other motor components from excessive wear and tear, enhancing the overall longevity of the motor.

Versatility: Suitable for a wide range of applications, including automotive, industrial machinery, and household appliances.

Carbon Brushes: The Heart of Motor Efficiency

Carbon brushes are a type of electric motor brush made primarily from carbon, chosen for its excellent conductive and wear-resistant properties. They are crucial for maintaining motor efficiency and are commonly used in a variety of electric motors.

Key Features:

High Conductivity: Carbon brushes offer superior electrical conductivity, ensuring efficient current flow between motor components.

Self-Lubricating: Some carbon brushes have self-lubricating properties, reducing friction and wear on the commutator or slip ring.

Heat Resistance: Designed to withstand high operating temperatures, making them suitable for demanding applications.

Customizable: Available in different grades and compositions to match specific motor requirements and operating conditions.

Benefits:

Reliable Performance: Carbon brushes provide consistent performance, ensuring the motor runs smoothly and efficiently.

Durability: High resistance to wear and tear means carbon brushes have a long service life, reducing the frequency of replacements.

Reduced Maintenance: Self-lubricating properties and robust design result in lower maintenance requirements, saving time and costs.

Enhanced Efficiency: By ensuring effective current transfer, carbon brushes help in maintaining optimal motor efficiency and performance.

Maintenance and Replacement: Key to Optimal Performance

Regular maintenance and timely replacement of electric motor brushes and carbon brushes are crucial for maintaining motor efficiency and preventing breakdowns.

Maintenance Tips:

Regular Inspections: Conduct periodic inspections to check for wear and tear. Brushes should be replaced when they reach the minimum recommended length or show signs of damage.

Clean Contact Points: Ensure the commutator or slip rings are clean to maintain optimal electrical contact and reduce wear.

Monitor Motor Performance: Be vigilant for any changes in motor performance, such as increased noise, reduced efficiency, or sparking, which may indicate brush wear.

Timely Replacements: Replace brushes promptly when they show signs of excessive wear or damage to avoid compromising motor performance.

Conclusion

Electric motor brushes and carbon brushes are integral to the smooth and efficient operation of electric motors. Understanding their functions, maintaining them regularly, and replacing them when necessary can significantly enhance motor performance and longevity. Whether in industrial machinery, automotive applications, or household appliances, investing in high-quality brushes and ensuring proper maintenance is essential for optimal motor functionality. Embrace the importance of these components to keep your motors running efficiently and reliably.

.png)

.jpg)

.png)

Write a comment ...