In the world of mechanical engineering, constant torque springs and slip rings are essential components that contribute to the efficiency and functionality of various systems. Understanding their functions and applications can provide insights into their significance in modern technology.

Constant Torque Springs: Steady Force in Motion

Constant torque springs are specialized springs designed to provide a consistent torque or rotational force throughout their range of motion. Unlike traditional springs, which exert varying forces depending on their displacement, constant torque springs maintain a steady force, making them ideal for applications requiring uniform tension.

Features of Constant Torque Springs

Consistent Force: The primary characteristic of constant torque springs is their ability to deliver a uniform force regardless of the angle of rotation. This makes them highly reliable for precise applications.

Compact Design: These springs are typically made from flat strips of metal wound tightly into a coil. This compact design allows for efficient use of space in various mechanical systems.

Durability: Made from high-quality materials, constant torque springs are durable and can withstand repeated cycles without significant wear and tear.

Versatility: They can be used in a wide range of applications, from automotive systems to medical devices, due to their ability to provide constant tension.

Applications of Constant Torque Springs

Retractable Mechanisms: Constant torque springs are commonly used in retractable systems such as tape measures, window shades, and seat belts, where consistent force is needed to rewind or retract the mechanism.

Electrical Contacts: These springs are used in electrical contacts to maintain constant pressure and ensure reliable connections in various electronic devices.

Counterbalancing: In applications such as laptop hinges and adjustable lighting fixtures, constant torque springs provide balanced and smooth motion, enhancing user experience and functionality.

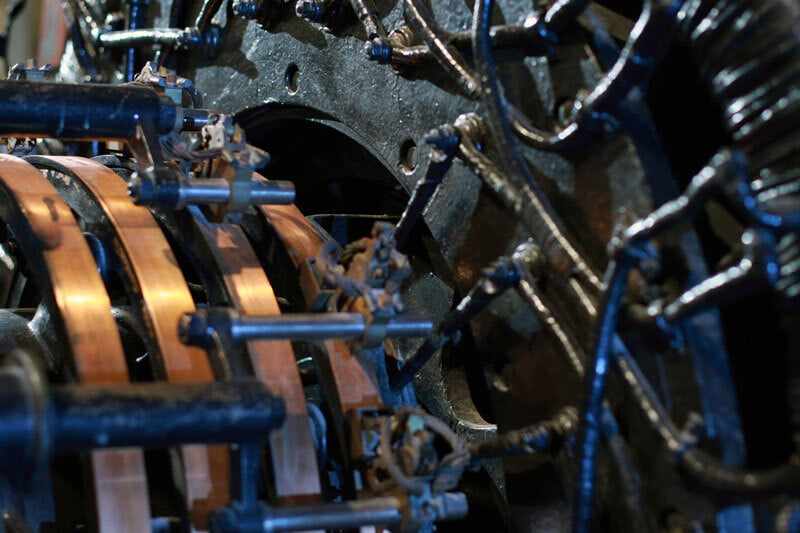

Slip Rings: Ensuring Continuous Electrical Connection

Slip rings, also known as rotary electrical joints or collectors, are devices that allow the transmission of electrical power and signals from a stationary to a rotating structure. They are crucial for applications where continuous rotation and electrical connection are required.

Features of Slip Rings

Rotational Transmission: Slip rings enable the transfer of electrical currents and signals between stationary and rotating parts, ensuring uninterrupted connectivity.

Versatility: They can transmit various types of signals, including power, data, and control signals, making them versatile for different applications.

Durability: Designed to withstand continuous rotation and harsh environmental conditions, slip rings are built for durability and long-term performance.

Compact and Efficient: Slip rings are compact in design, allowing them to be integrated into various mechanical systems without occupying excessive space.

Applications of Slip Rings

Wind Turbines: Slip rings are used in wind turbines to transfer electrical power from the rotating blades to the stationary power grid, ensuring efficient energy conversion and distribution.

Robotics: In robotic systems, slip rings provide continuous electrical connection to rotating joints, enabling the transmission of power and control signals for precise movement.

Medical Imaging Equipment: Slip rings are essential in medical imaging devices like CT scanners, where they facilitate the transmission of data and power between rotating components and stationary data processing units.

Rotary Tables: In industrial automation, slip rings are used in rotary tables to maintain electrical connections while allowing continuous rotation, enhancing manufacturing efficiency.

Conclusion

Constant torque springs and slip rings are integral components in various mechanical and electrical systems. Constant torque springs provide consistent force and reliable performance in retractable mechanisms and counterbalancing applications. Slip rings ensure continuous electrical connectivity in rotating systems, making them indispensable in industries such as wind energy, robotics, and medical imaging. Understanding these components' features and applications highlights their importance in modern engineering and technology.

.png)

.jpg)

.png)

Write a comment ...