In the world of electric motors, traction motor carbon brushes and electric motor brush holders play a crucial role in ensuring efficient and reliable operation. These components are fundamental to the functionality of various motor-driven systems, from industrial machinery to electric vehicles. This article delves into the importance, functionality, and maintenance of traction motor carbon brushes and electric motor brush holders.

Traction Motor Carbon Brushes

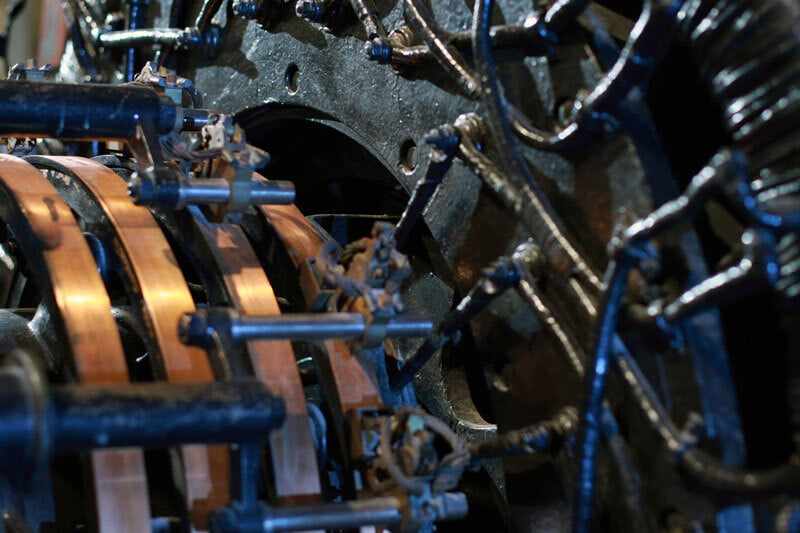

Definition and Function: Traction motor carbon brushes are small, yet vital, components used in electric motors to conduct current between stationary wires and rotating parts. These brushes are typically made from a mixture of carbon and graphite, which provides a good balance of conductivity and durability. In traction motors, which are commonly used in locomotives and electric vehicles, carbon brushes facilitate the transfer of electrical current to the motor's rotating armature, enabling motion.

Importance: The efficiency and longevity of a traction motor heavily depend on the quality and condition of its carbon brushes. Well-maintained brushes ensure consistent electrical contact, minimize energy loss, and reduce the risk of damage to other motor components. Conversely, worn or damaged brushes can lead to poor motor performance, increased wear on the commutator, and even motor failure.

Maintenance: Regular inspection and maintenance of carbon brushes are essential. Signs of wear, such as reduced brush length or uneven wear patterns, indicate that it's time for replacement. Additionally, maintaining clean and smooth commutator surfaces helps prolong brush life and improve motor efficiency.

Electric Motor Brush Holders

Definition and Function: Electric motor brush holders are mechanical assemblies designed to secure the carbon brushes in place and ensure consistent contact with the commutator or slip rings. These holders are typically constructed from robust materials such as metal or high-grade plastic to withstand the operational stresses and temperatures within the motor.

Importance: Brush holders are critical for maintaining the correct position and pressure of the brushes against the commutator. Proper alignment and pressure are vital for optimal electrical contact and minimizing brush wear. Any misalignment or insufficient pressure can lead to sparking, excessive wear, and potential motor damage.

Maintenance: Regular maintenance of brush holders involves checking for wear, corrosion, and proper spring tension. Springs in the brush holders need to provide adequate pressure to ensure good contact without causing excessive friction. Regular cleaning of the holders and the surrounding area helps prevent debris buildup, which can interfere with brush operation.

Conclusion

Traction motor carbon brushes and electric motor brush holders are indispensable components in the efficient operation of electric motors. Ensuring these components are in good condition through regular maintenance and timely replacement can significantly enhance motor performance and longevity. Whether in industrial applications or electric vehicles, the health of these components directly impacts the reliability and efficiency of the entire motor system. By understanding their roles and maintaining them properly, operators can ensure smooth and effective motor operation, leading to better overall system performance.

.png)

.jpg)

.png)

Write a comment ...