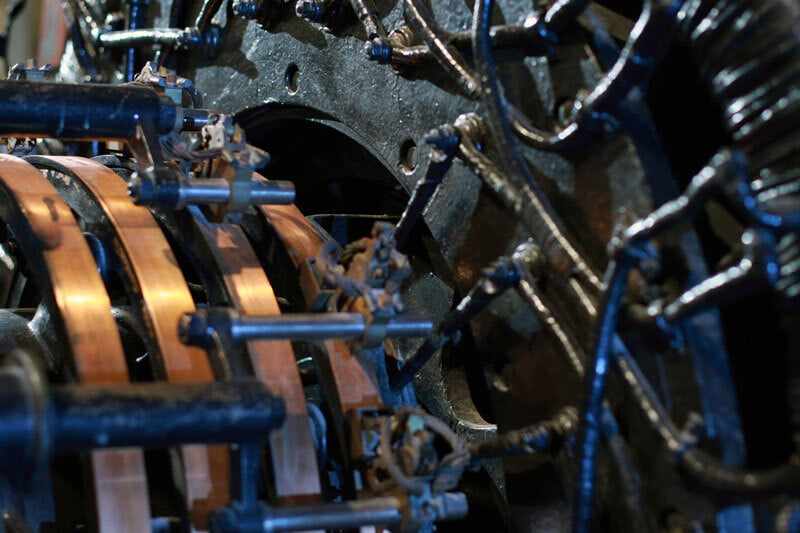

Carbon brush holders and slip ring assemblies play crucial roles in various electromechanical systems, ensuring efficient electrical contact and transmission in rotating machinery. Understanding the manufacturers behind these components sheds light on their quality, reliability, and applications in modern industrial and commercial settings.

Carbon Brush Holders: Ensuring Reliable Electrical Contact

Carbon brush holders are devices that secure and maintain carbon brushes in place, facilitating electrical contact with rotating components such as slip rings. These holders are essential for applications requiring consistent electrical transmission and minimal wear over extended use.

Key Features of Carbon Brush Holders

Material Quality: Made from durable materials such as brass, stainless steel, or engineered plastics, carbon brush holders offer robust support and electrical conductivity.

Adjustability: Many carbon brush holders feature adjustable mechanisms to accommodate different brush sizes and configurations, ensuring precise contact and optimal performance.

Ease of Maintenance: Designed for easy installation and maintenance, carbon brush holders simplify brush replacement and inspection, reducing downtime in critical machinery.

Environmental Compatibility: Some holders incorporate features like dust seals or protective coatings to enhance performance in challenging environments, such as industrial machinery or outdoor equipment.

Applications of Carbon Brush Holders

Electric Motors: Carbon brush holders are integral to electric motor assemblies, where they maintain contact between brushes and commutators or slip rings, enabling reliable power transmission.

Generators: In generator systems, carbon brush holders ensure continuous electrical contact with slip rings, facilitating the conversion of mechanical energy into electrical power.

Wind Turbines: Carbon brush holders play a vital role in wind turbine generators, where they help transfer electrical currents from rotating components to stationary systems, ensuring efficient energy production.

Slip Ring Assemblies: Enabling Continuous Electrical Connectivity

Slip ring assemblies are electromechanical devices that facilitate the transmission of electrical power and signals from stationary to rotating parts. These assemblies are critical in applications requiring uninterrupted power transfer and signal integrity across rotating interfaces.

Key Features of Slip Ring Assemblies

Contact Material: Slip ring assemblies utilize various contact materials such as precious metals (e.g., silver, gold) or durable alloys to ensure low electrical resistance and minimal wear during operation.

Modular Design: Many slip ring assemblies feature modular configurations, allowing customization for specific applications with varying current capacities, signal types, and environmental conditions.

High-Speed Capability: Advanced slip ring designs support high rotational speeds while maintaining stable electrical performance, suitable for demanding industrial machinery and aerospace applications.

Sealing and Protection: Some assemblies incorporate seals, coatings, or housing materials to protect internal components from contaminants, moisture, and temperature extremes, enhancing longevity and reliability.

Applications of Slip Ring Assemblies

Robotics: Slip ring assemblies enable continuous power and signal transmission in robotic arms and joints, facilitating precise control and movement in industrial automation and research applications.

Medical Devices: In medical imaging equipment like MRI scanners, slip ring assemblies transmit data and power across rotating gantries, ensuring uninterrupted operation and diagnostic accuracy.

Broadcasting: Broadcast cameras and antennas use slip ring assemblies to maintain signal connectivity during pan-and-tilt movements, supporting live broadcasts and telecommunications.

Leading Manufacturers of Carbon Brush Holders and Slip Ring Assemblies

Mersen: Known for its comprehensive range of electrical components, Mersen offers high-performance carbon brush holders and slip ring assemblies designed for industrial applications requiring reliability and durability.

Morgan Advanced Materials: Morgan Advanced Materials specializes in carbon brush holders and slip ring technologies, providing customized solutions for demanding environments in automotive, aerospace, and renewable energy sectors.

Helwig Carbon Products, Inc.: Helwig Carbon Products manufactures carbon brush holders and assemblies tailored to specific motor and generator requirements, emphasizing quality craftsmanship and technical expertise.

Deublin Company: Deublin Company is a global leader in slip ring technology, offering innovative solutions for industries such as packaging, printing, and wind power, with a focus on high-speed and high-frequency applications.

Schleifring North America: Schleifring North America provides advanced slip ring assembly manufacturers and rotary joint solutions for military, aerospace, and industrial markets, emphasizing precision engineering and reliability under extreme conditions.

Conclusion

Carbon brush holders and slip ring assemblies are integral components in electromechanical systems, ensuring reliable electrical contact and transmission in rotating machinery across various industries. Manufacturers like Mersen, Morgan Advanced Materials, and Helwig Carbon Products play key roles in developing and supplying these critical components, supporting industrial automation, renewable energy generation, and advanced technology applications worldwide. Understanding their capabilities and product offerings helps businesses and engineers select optimal solutions for their specific operational needs and performance requirements.

.png)

.jpg)

.png)

Write a comment ...