Compression springs and motor replacement carbon brushes are integral components in mechanical and electrical systems, respectively, each playing a crucial role in ensuring optimal performance and longevity. Here’s an exploration into their functions, applications, and importance in various industries.

Compression Springs: Mechanics and Applications

Compression springs are mechanical devices designed to store energy when compressed and release it when the compressive force is removed. They are characterized by their ability to resist compressive forces and return to their original length after being compressed.

Key aspects of compression springs include:

Design and Construction: Compression springs are typically helical coils made from various materials such as steel, stainless steel, or even non-metallic materials like plastics. Their design includes parameters like coil diameter, wire diameter, and number of coils, which determine their spring rate and load capacity.

Functionality: When a compressive force is applied, compression springs absorb the energy by compressing and store it as potential energy. When the force is released, they expand back to their original length, releasing the stored energy.

Applications: Compression springs find applications in a wide range of industries and products, including automotive suspensions, industrial machinery, medical devices, consumer electronics, and aerospace systems. They are used for shock absorption, vibration isolation, force generation, and maintaining component alignment.

Design Considerations: Engineers select compression springs based on factors such as load requirements, available space constraints, environmental conditions (temperature, corrosion resistance), and desired spring characteristics (stiffness, deflection range).

Motor Replacement Carbon Brushes: Essential Components in Electrical Systems

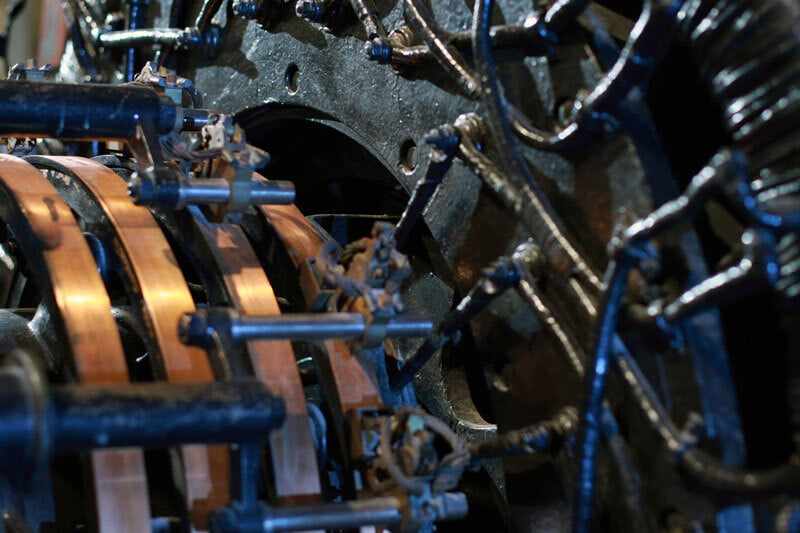

Carbon brushes are crucial components in electric motors and generators, facilitating electrical contact between stationary and rotating parts. Over time, these brushes wear out and require replacement to maintain efficient motor operation. Key aspects of motor replacement carbon brushes include:

Functionality: Carbon brushes transfer electrical current from the stationary part (stator) to the rotating part (rotor) of an electric motor or generator. They are typically made from a mix of graphite and other materials, chosen for their conductivity, durability, and friction properties.

Wear and Replacement: Due to friction and electrical arcing during operation, carbon brushes gradually wear down. Regular inspection and replacement of worn brushes are essential to prevent motor performance degradation and potential damage to commutators or slip rings.

Selection and Installation: When replacing carbon brushes, factors such as brush size, shape, material composition, and compatibility with the motor’s operating conditions (voltage, current, speed) must be considered to ensure optimal performance and longevity.

Applications: Carbon brushes are used in a wide range of electric motors and generators across industries, including industrial machinery, power tools, household appliances, automotive components, and renewable energy systems (wind turbines, hydroelectric generators).

Importance in Maintenance and Performance

Both compression springs and motor replacement carbon brushes play critical roles in maintaining the efficiency, reliability, and longevity of mechanical and electrical systems:

Reliability: Proper selection and maintenance of compression springs and carbon brushes contribute to the overall reliability and operational uptime of equipment.

Performance: Ensuring that these components are in optimal condition enhances system performance, reduces downtime, and minimizes maintenance costs.

Safety: Regular inspection and replacement of worn components improve safety by preventing potential failures that could lead to operational hazards or equipment damage.

Conclusion

Compression springs and motor replacement carbon brushes are indispensable components in mechanical and electrical systems, each contributing uniquely to system functionality and performance. Understanding their roles, applications, and maintenance requirements is essential for engineers and maintenance professionals across various industries.

Optimizing System Efficiency: The Role of Compression Springs and Motor Replacement Carbon Brushes

This content provides insights into the functions, applications, and importance of compression springs and motor replacement carbon brushes in mechanical and electrical systems, emphasizing their role in ensuring optimal performance and reliability.

.png)

.jpg)

.png)

Write a comment ...